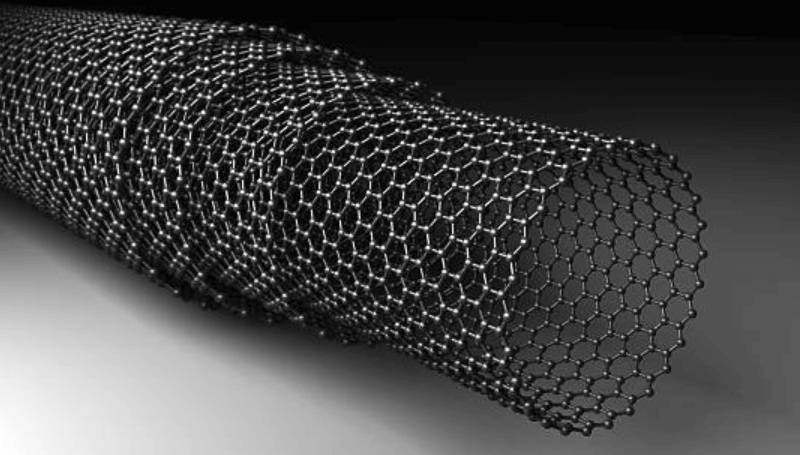

Carbon atoms are arranged in a honeycomb lattice in graphene. It’s a miracle material because of how well it performs in mechanical, electrical, and thermal contexts. Electronics, energy storage, composites, sensors, biomedicine, and more are all possible applications. The manufacturing of graphene and its potential uses are explored in this article.

Because of its extraordinary characteristics, graphene has broad applicability. Because of its high electrical conductivity and electron mobility, it has the potential to be used in transistors, logic gates, and sensors. With a high specific surface area, excellent electrical conductivity, and favorable mechanical qualities, it is ideally suited for use in supercapacitors and batteries. Because of its potential for enhancing the mechanical and electrical properties of composite materials including plastics and metals, it is increasingly being considered a promising addition. Because of its biocompatibility and high surface area, it is used in a variety of biomedical applications.

Research is continue to uncover even more of this incredible material’s potential applications, all thanks to graphene’s remarkable characteristics and flexible manufacturing options.

Due to its high surface-to-volume ratio and two-dimensional structure, graphene is a promising heat conductor. The thermal characteristics of graphene vary with its layer count, defect density, and surrounding conditions. The hot and cold reactions of graphene are discussed in this response.

Graphene is an excellent heat conductor at high temperatures. It has a far higher thermal conductivity than most metals, about 5000 W/mK. Graphene has a melting point of 4,500 K, making it resistant to extremely high temperatures. Graphene can be harmed by fire and high temperatures because of its imperfections and impurities.

Graphene shows intriguing thermal properties at low temperatures. Graphene’s thermal conductivity decreases below 10 K due to phonon dispersion by flaws, edges, and impurities. Graphene is therefore highly effective as a thermal insulator at low temperatures. Graphene becomes a superconductor at very low temperatures.

Because of its thermal characteristics, graphene can withstand high temperatures and shows promise as a low-temperature thermal insulator. Its thermal characteristics are affected by structural and environmental factors including flaws, impurities, and temperature.

Aerogel and graphene can be used to make high-performance materials, yes. Aerogel is a nanoparticle network with a high surface area and low density, making it a porous material. It provides excellent protection against the transfer of sound and heat. The mechanical, electrical, and thermal properties of the two-dimensional substance graphene are unprecedented. By bringing these materials together, a new category of high-performance materials is born.

Graphene aerogel is a porous and lightweight three-dimensional network of graphene sheets. Graphene aerogel’s large porosity and graphene structure give it exceptional thermal, electrical, and mechanical capabilities. Several potential applications exist, including energy storage, catalysis, and environmental cleanup.

Graphene oxide aerogel is used as a mold for creating graphene aerogel composites. Graphene is synthesized by chemically reducing an aerogel of graphene oxide, which serves as a template for a porous network of graphene sheets. It excels in areas like surface area, mechanical strength, and electrical conductivity. High-performance materials can be made using graphene and aerogel. New applications for these materials are the focus of continuing research.

Pure graphene is currently unprintable with common 3D printing techniques. Graphene, a two-dimensional substance with a thickness of only one atom, needs to be treated in a certain way to preserve its unusual qualities. Graphene-based materials may now be 3D printed thanks to the discovery of binders, additives, and hybrid materials.

Composites based on graphene can be 3D printed. Graphene-based inks generated from polymers or metal nanoparticles can be used for inkjet or extrusion-based 3D printing. The mechanical, electrical, and thermal capabilities of composites are superior to those of their base materials.

Graphene oxide (GO) can be printed and then reduced to graphene using direct ink writing (DIW) or stereolithography (SLA). Chemical or heat reduction of the printed GO results in graphene. Graphene structure form and characteristics are influenced by printing factors and reduction procedures.

Graphene structures are printed in pure form using two-photon lithography (TPL). TPL involves the polymerization of graphene oxide solution through laser to produce 3D graphene structures. These structures benefit greatly from pure graphene’s superior mechanical, electrical, and thermal properties.

Although graphene is challenging to 3D print, a number of techniques have been developed to manufacture composites and structures based on graphene that have unique features. Researchers are looking at the potential of 3D printing with graphene-based materials and techniques in the fields of energy storage, electronics, and biomedical engineering.

Graphene’s potential advantages as an additive in cement and ceramics have been the subject of multiple research projects. Graphene can increase the concrete’s compressive strength, toughness, permeability, and durability. After graphene oxide or reduced graphene oxide is added to the concrete mixture as a powder or dispersion, the composite can be cast or molded in the usual way.

Graphene enhances the mechanical, electrical, and thermal conductivity of concrete, expanding its use in a variety of building projects. Self-sensing or self-healing structures can be created using graphene-modified concrete, which can detect damage or cracks and then repair itself.

Applying graphene to ceramics boosts their performance and utility by enhancing their mechanical, thermal, and electrical properties. Graphene can be introduced into the ceramic matrix using either co-precipitation, sol-gel, or electrospinning, depending on the application and needs.

Graphene-based ceramic composites are ideal for use in aerospace, automotive, and biomedical engineering due to their high mechanical strength, fracture toughness, and wear resistance. Graphene increases the thermal stability and electrical conductivity of ceramics, making them ideal for high-temperature resistance and electrical insulation.

Graphene’s potential to improve the characteristics and performance of concrete and ceramics suggests that this combination may lead to next-generation materials. The use of graphene in these products has the potential to revolutionize the building and manufacturing sectors by making them more sustainable and competitive.

In conclusion, graphene is a miracle material due to its exceptional properties in mechanical, electrical, and thermal contexts. Several manufacturing techniques are available to synthesize graphene, including mechanical exfoliation, chemical vapor deposition (CVD), epitaxial growth, and chemical reduction. Graphene has a broad range of applications in various fields, including electronics, energy storage, composites, sensors, and biomedicine. Graphene’s thermal characteristics vary with its layer count, defect density, and surrounding conditions, making it an excellent heat conductor at high temperatures and a thermal insulator at low temperatures. Graphene aerogel, a three-dimensional network of graphene sheets, can be used to create high-performance materials with exceptional thermal, electrical, and mechanical capabilities. Although pure graphene is currently unprintable with common 3D printing techniques, composite structures based on graphene can be 3D printed using graphene-based inks, with potential applications in energy storage, electronics, and biomedical engineering. Finally, graphene can also be used as an additive in cement and ceramics to increase their compressive strength, toughness, permeability, and durability.